PCB Manufacture

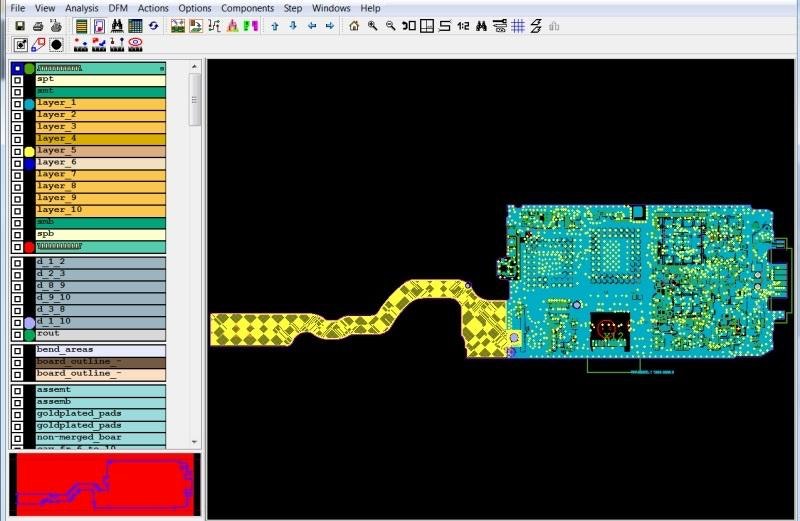

Valor NPI

O software Valor NPI combina as melhores soluções de DFM da classe com modelamento de manufatura de produto, permitindo introdução de novos produtos mais eficientes e com menor custo. A validação do projeto de PCB levando em conta a capacidade dos fornecedores assegura a mais alta qualidade dos produtos e o custo reduzido.

A solução contém acima de 1000 regras de manufatura para serem verificadas. Com um DFM inteligente e automático guia para uma análise eficiente e identifica aspectos do PCB que impactam nos índices de defeitos, custo e confiabilidade.

O acesso a VPL (Valor Library Parts) um biblioteca vasta e completa com milhões de modelos de componentes permite validação da placa e de soldagem utilizando prototipagem virtual.

Uma abrangente análise DFM cobre a fabricação, montagem, teste, substrato flexível/rígido-flexível e painel.

Possibilita fácil criação de painéis de montagem otimizados para economizar materiais.

A análise de BOM de manufatura x Projeto assegura que não haja discrepâncias que podem ser custosas quando encontradas tardiamente na produção.

Permite validação batendo todos os parts qualificados em uma AVL (Approved Vendor List).

Utilize o Valor NPI para analisar a sua placa para questões de DFM relacionados com:

- Fabricação

- Montagem

- Microvias

- Circuitos rígidos e flexíveis

- Painel

- Substrato de Package

Ao invés de enviar inúmeros documentos e desenhos para transmitir instruções de manufatura, deixe o Valor NPI distribuir todas as informações necessárias através de um Modelo de Manufatura de Produto. Isto economiza tempo do lado de criação e validação do pacote e é mais eficiente e menos sujeito a erro para utilização do seu fornecedor da mesma forma.

Checks Realizados:

Assembly

- Alternate Parts

- Automatic Insertion

- Component

- Embedded Passives

- Fiducial

- Padstack

- Pin-to-Pad

- Solderpaste

- Testpoint

Panel

Substrate

- Signal

- Soldermask

Fabrication

- Drill

- Etching

- Power & Ground

- Profile

- Signal Layer

- Silkscreen

- Soldermask

- Surface

Flex/Rigid-flex

Microvia

- Drill

- Signal

- Soldermask

Signal Layer Net Type